The production of recyclable steel has become possible thanks to new technology discovered. Will standardization of this innovative proposal be possible? Here are the main keys to what has been developed

Steel has accompanied humans for centuries. Thanks to its technical qualities, It has become an essential component in the industrial sector. Now, new research has just come up with a new formula for obtaining so-called eco-steel. What is strange is that it is available from tainted rights, A formula that will encourage the practice of recycling In the medium and long term. What are the characteristics of this new technology and why could it have a significant impact on the economy?

Environmental steel, new recycling formula to obtain this first-class raw material

To understand the importance of this proposal, it is necessary to record the scale of emissions associated with steel. It is believed that up to 8% of carbon emissions are in the atmosphere Comes directly from foundry operations To get steel. The need to obtain an alternative product, even partially, is what prompted a team of researchers to conduct the study. the Research conclusions They are optimistic, as a new line is being opened regarding the study of this alloy.

The team of professionals at the Max Planck Institute for Eisenfurschung was able to quickly and inexpensively recycle the red sludge byproduct of aluminum to obtain what is known as Recyclable steel. Interestingly, the initial formulation undergoes a theoretically easy-to-implement process, so its standardization in industry may be possible in the coming years. It is believed that thanks to this new technology and production process A total of 770 million tons of steel can be sold From this new category.

In order to understand how this technology works, It is necessary to turn into aluminum waste. This alloy, over time, is capable of generating a type of red sludge due to oxidation. This polluted waste can end up in the natural waters of rivers, swamps and seas. It is currently believed There could be up to 4.7 billion tons of red clay existing, so the placement of these spaces can be significantly improved.

Some alloys derived from steel are considered one of the five hardest materials in the world, so they are essential This element continues to exist in multiple sectors related to the industrial field. This new proposal may be of particular importance in the medium term if it is confirmed that this recyclable steel has a composition practically identical to the original formulation.

With only 15 grams of red clay A total of 2.6 grams of mineral iron can be obtained, a level of proficiency that can be easily scalable. It is expected that in the long term a large amount of sustainable steel can be obtained thanks to this revolutionary system. At the same time, we will have to continue looking for other alternatives that can reduce the human carbon footprint in production. It is true that we are not talking about the most valuable element in the world, but it is an important advance in reducing the cost of producing steel, both conventional and recycled.

“Beer enthusiast. Subtly charming alcohol junkie. Wannabe internet buff. Typical pop culture lover.”

:quality(85)/cloudfront-us-east-1.images.arcpublishing.com/infobae/7LFLBSHU4FG4FJIYGXW2IUHTDM.jpg)

:quality(85)/cloudfront-us-east-1.images.arcpublishing.com/infobae/7H35DR4K5BDFDMQV5GYX4MUDEA.jpg)

:quality(85)/cloudfront-us-east-1.images.arcpublishing.com/infobae/DYNT4CH2PNFCDKYIR4QDOERVD4.jpg)

More Stories

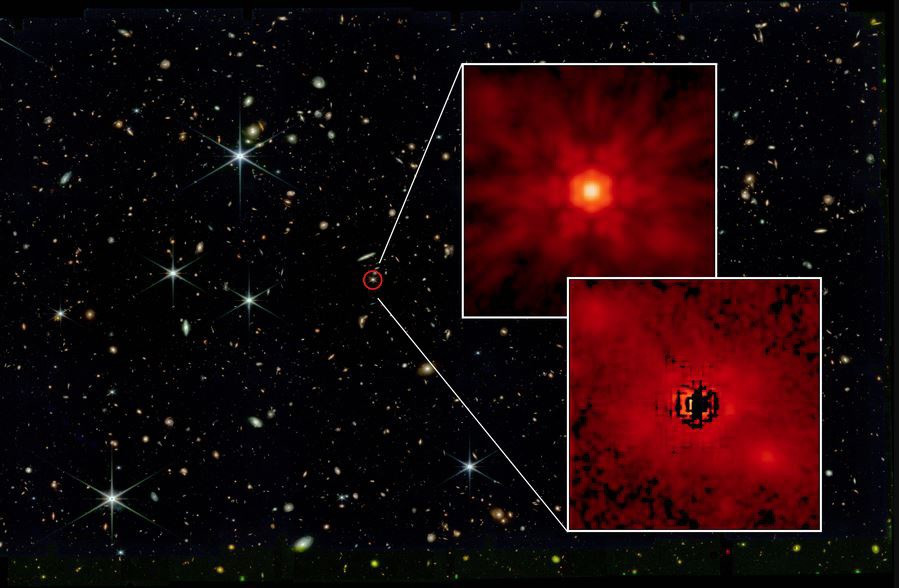

They noticed the elusive starlight surrounding ancient quasars

The first launch of the Starliner ship arrives with astronauts on board

A wonderful trip to the prestigious Xerox PARC laboratory