Aluminum is an essential component of the aerospace industry. But it faces a difficulty: corrosion.

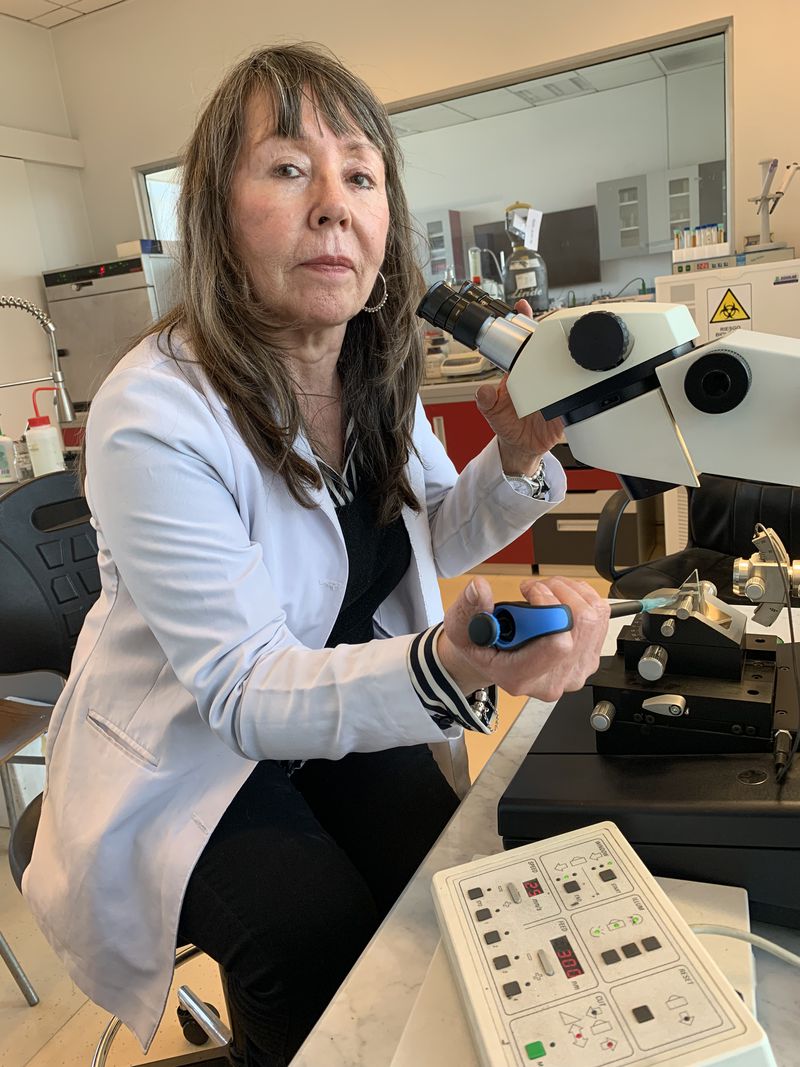

To avoid this deterioration, a group of Chilean researchers led Maritza Baez, Ph.D. in Corrosion Science and Engineering from Victoria University of Manchester, England, and Professor of Chemistry and Biology at yo de santiagoShe is currently working on developing an investigation Designed to protect lightweight aluminum alloy that can be used in building Planes and spaceships of the future.

Work directed towards him Corrosion protection of aluminum, copper and lithium alloys, The mixture that scientists are experimenting with. Aluminum Developed Variants “Due to the unique combination of light weight, high strength and ease of fabrication, aluminum alloys are a mainstay of the aerospace industry. Today, more than ever, this issue is gaining importance, due to the increase in the number of aeronautical subsystems and because of Aerospace exploration and planetary colonization procedures. However, for its application in building aerospace systems, aluminum must be alloyed to significantly improve its mechanical properties,” explains Maritsa Bays, who was recently incorporated into Chilean Academy of Sciences.

Combining with lithium could have special results in reducing aircraft weight, Because when talking about this mineral, the needs and possibilities are eminently active. However, at present, the progress of air transport also appears to be of particular interest in the development of light alloys, as it allows to reduce, on the one hand, CO2 انبعاثات emissions On the other hand, Facilitate the exploration and conquest of space.

“It is precisely in this area where the development of aluminum-lithium alloys takes on strategic importance. Reducing the material density is accepted as the most effective way to reduce the structural weight of an aircraft. Lithium (density of 0.54 g/cm3) is one of the few elements with a high degree of solubility in aluminum The latter is important, because for every 1% added, the density of the aluminum alloy decreases by 3%. Lithium is also unique among the more soluble alloying elements, as it causes a significant increase in hardness (4.4% for every 1% added of Li)” Bayes says.

Regarding Chile, the Doctor of Corrosion Sciences and Engineering says that the country is in a privileged position in meeting the needs posed by the development of the industry on which the group of scientists focus their research.

“The main question we must ask ourselves is: How can we turn lithium into diamonds for our country? This question is not easy to answer, but there is a certain possibility that we are creating spaces for technology transfer to developed countries, in order to finally build processing plants that allow value to be added to lithium. Today, Chile is doing research on lithium. However, these studies are not enough to make the leap in technological development that we need. So another suggestion could be that, if the technology is already deployed in developed countries, wouldn’t it be great to continue to advance in basic research, but with basic guidelines, that bring us closer to the technological challenges that lithium brings us? “It would be great, in Chilean universities, in the consortium of public and private universities, to create incubators for technological platforms.”

In his opinion, this could lead to “the creation of two or more potential industries for Chile, the development of which is from their origin sustainable and sustainable. They not only add value to our minerals, but add that, and this is very important to highlight, In addition to providing employment for Chilean professionals, they also contribute strategically to the country’s development.”

Although Dr. Bays cautions that incorporation of lithium into aluminum increases the interaction of surfaces and therefore it is very important to establish protocols and methodologies for corrosion protection: “Alloy compositions, manufacturing processes and mechanical treatments both promote the generation of conductive regions of different configuration. When these regions come into contact with Environments that allow ionic conduction, they stimulate galvanic cells and thus marked degradation of the surface, which can lead to perforation, i.e. catastrophic failure of the structure. To reduce any possibility of catastrophic failure, Corrosion protection processes become transcendental.”

The team also consists of physicians in chemistry, Manuel Azucar and Lisa Muñoz, and academics and researchers from USACH. Nelson Figar, an academic and researcher at the Chilean Air Force and Dr. Claudia Alvarado, also a researcher at FACH,

The scientist explains that in general the study of the susceptibility of materials to corrosion is carried out by examining the behavior of metal surfaces “against different atmospheric and aquatic environments, which include the biosphere, biofluids, that is, the presence of microorganisms. In this context, the role of smart anti-corrosion coatings for the protection of aluminum, copper and lithium alloys has begun to be evaluated.

add that These compounds are in the domain of so-called “smart materials”, due to their ability to “respond to changes in the environment”. Like for example what would happen to a layer of paint. “It can have mechanical damage and be locally uncoated. So we want to quickly cover that area that was left uncoated, but for that coating to happen, it has to be associated with some degree of intelligence.”

In the current research process, nanomaterials (of very small dimensions) are used, “which are incorporated into the coating and catalyze controlled oxidation that prevents, for example, exposure of the damaged area, or in another example, bacteria can colonize the surface of the alloy.”

Bayes asserts that they are born through these procedures Products’ that can be encountered Air Navigation Challenges: Changes in relative humidity, sudden changes in temperature, changes in composition in the atmosphere and biosphere.”

What he describes through the example of a plane that takes off from Arturo Merino Benítez airport: “It does so with relative temperature and humidity, and its entire structure is in contact with the surface. But what happens when the plane actually arrives in the Caribbean, or simply arrives in São Paulo, where there is Much higher humidity, much higher temperatures?The protection that has been put on the ingot must withstand.A plane takes off, say in summer, from 30°C, but when it reaches its maximum navigable altitude (about 12,000 metric tons), we have – 50°C An anti-corrosion coating is of course expected to be able to respond to these temperature changes without breaking.Any material one uses to protect metal, in this case aluminum and its alloys, must have the ability to withstand pressure shocks and temperature shocks, from among other variables.

“Beeraholic. Friend of animals everywhere. Evil web scholar. Zombie maven.”